Bricks have been a versatile building material throughout our history. It is durable and has high compressive strength, in turn making it suitable for use in construction and civil engineering projects as a structural element. Beyond the mechanical properties of brick, there are some aesthetic appeals that favor its use in architectural applications. Therefore, this article will help you understand the various types of bricks and its application.

Types of Bricks:

Classification factors:

- Manufacturing process

- Based on the materials used

A . Based on the manufacturing process, the types of bricks are mainly classified into two types:

- Sun-dried or unburnt bricks

- Burnt bricks

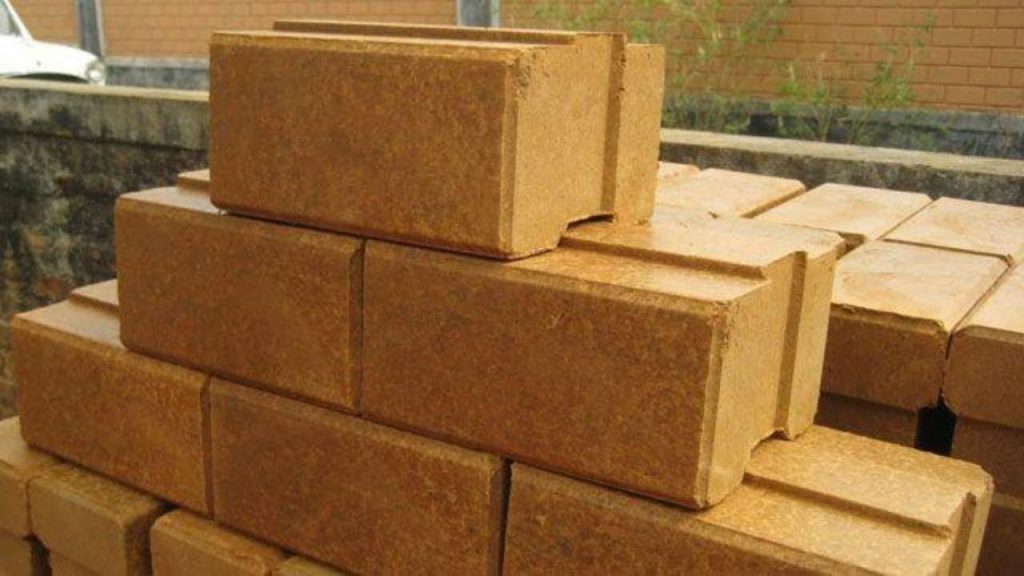

1. Sun-dried or unburnt bricks

These are less durable and used for temporary structures.

Unburnt bricks preparation involves 3 steps and they are: preparation of clay, molding, and drying.

After Molding, use sunlight to dry the bricks instead of baking them. So, they are not that much stronger and also have less water resistance and less fire resistance. These types of bricks are not suitable for any permanent structures.

2. Burnt bricks

You can make burnt clay bricks by placing molded clay into a kiln and then firing it up.

Burnt bricks can be of different quality and they are:

a. First class bricks

b. Second class bricks

c. Third class bricks

d. Fourth class bricks

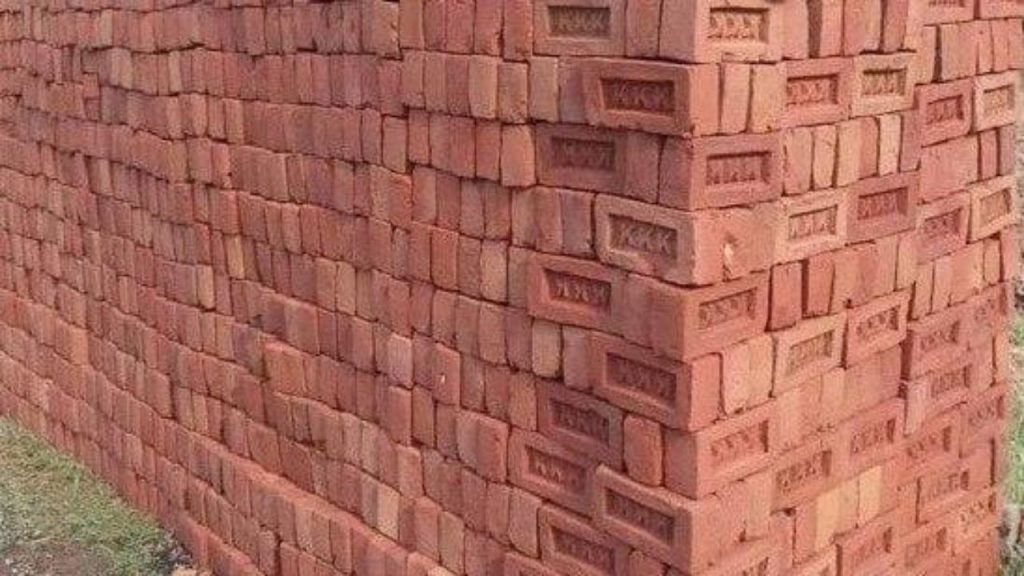

a. First Class Bricks

First class bricks are good quality bricks when comparing to other types of bricks. They are molded by table-molding and burnt in large kilns. So, these first class bricks contain standard shape, sharp edges and smooth surfaces. They are more durable and have more strength. They can be used for permanent structures.

However, because of their good properties they are costlier than other classes. These are 19 x 9 x 9 cm in size. Its compressive strength shall not be less than 140 kg/cm2. And they wont absorb more than 20% of water when immersed in water for 24 hours. Can use this type of brick for all types of construction in the exterior walls. They are also suitable for flooring.

https://buildnext.in/8-x-4-x-3-red-brick-grade-1-192721

b. Second Class Bricks

Second class bricks are of moderate quality and they are molded by the ground-molding process. These bricks are also burnt in kilns. But because of ground molding, they do not have smooth surfaces and sharp edges. The shape of bricks is also irregular due to unevenness in the ground. These also will give best results in strength and durability.

Smooth plastering is required on the brick structure. Its compressive strength will not be less than 70 kg/cm2. We can use these types for exterior work and then plastering has to be done. Also, you can use for interior works, but may not use for flooring.

https://buildnext.in/8-x-4-x-3-red-brick-grade-2-192723

c. Third Class Bricks

Third class bricks are of poor quality which are generally used for temporary structures like unburnt bricks. These are not suitable for rainy areas. They are ground-molded type bricks which are burnt in clamps. The surface of these bricks is rough and they have unfair edges. Its compressive strength lies between 35 – 70 kg/cm2 and absorption between 22 – 25 percent.

https://buildnext.in/8-x-4-x-3-red-brick-grade-3-192725

d. Fourth Class Bricks

Fourth class bricks are very poor quality bricks and not used as bricks in the structure. You can crush and use it as aggregates in road construction, foundations and floors as a coarse aggregate material. They are obtained by over burning, because of this they gets overheated and obtains brittle nature. So, they can break easily and not suitable for construction purpose.

B. Based on the materials used,

I. Fly Ash Brick

Fly ash bricks are manufactured using fly ash and water. These bricks have better properties than that of clay bricks and great resistant to freeze thaw cycles. They contain a high concentration of calcium oxide, which is used in cement production, thus it is also known as self-cementing brick.

Fly ash bricks are lightweight and thus it reduces the self weight of structures. The advantages of fly ash bricks over clay bricks are that they have high fire insulation, high strength, uniform sizes for better joints and plaster, lower water penetration, does not require soaking before used in masonry construction.

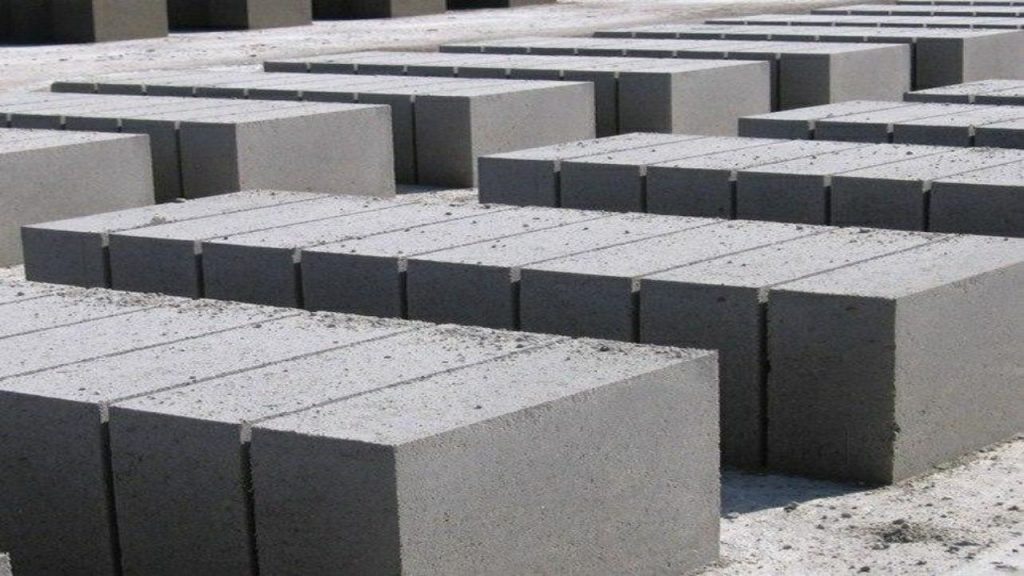

II. Concrete Bricks

Concrete, bricks are manufactured using concrete with ingredients as cement, sand, coarse aggregates and water. These bricks can be manufactured in the required sizes. The advantages of using concrete, bricks over clay bricks are that they can be manufactured at a construction site, reduces the quantity of mortar required.

You can use concrete bricks for the construction of masonry and framed buildings, facades, fences, and provides excellent aesthetic presence.

Depending upon the structure, shape, size, and manufacturing processes concrete blocks are broadly classified into 8 types and they are:

i. Solid Concrete Blocks

ii. Hollow Concrete Blocks

iii. Engineering Bricks

IV. Sand Lime or Calcium Silicate Bricks

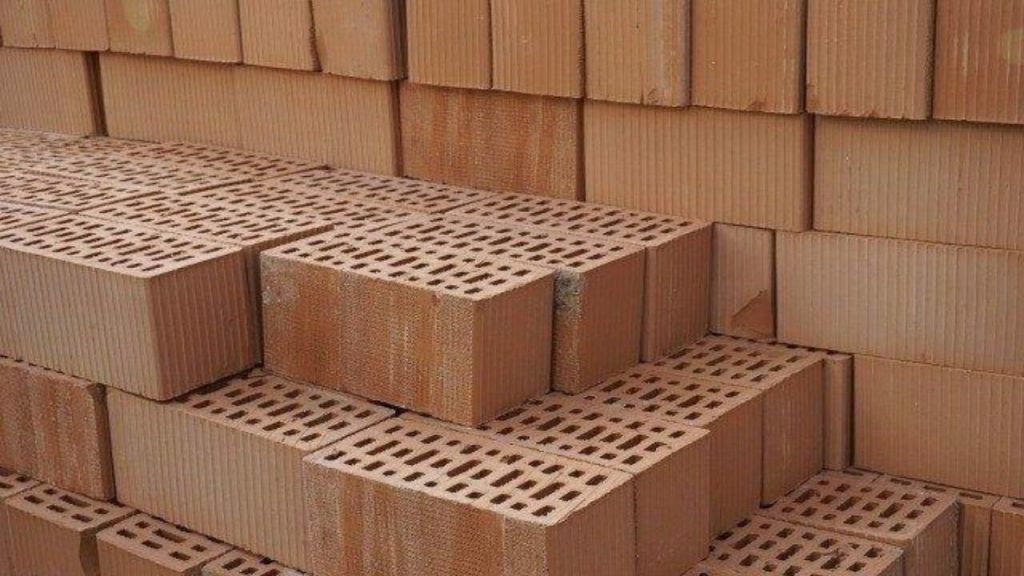

V. Porotherm Smart Bricks Or Eco Bricks

VI. Autoclaved Aerated Concrete (AAC Blocks)

VII. CLC is called Cellular Light Weight blocks

VIII. Interlocking bricks

The above listed bricks will be explained in detail in future articles.

Have you got a clear idea about bricks? Please share your thoughts in the comment section.