Concrete is a composite material which we can easily mold to any shape with high strength and durability. Even though steel structures are in use instead of concrete, maintenance cost for them is comparatively higher. As a result, it is not affordable for small scale constructions. Therefore, concrete is the best choice for are an easier, efficient and economic way for construction projects.

Concrete is an artificial stone-like mass, which is a composite material created by mixing binding material (cement or lime) along with the aggregate (sand, gravel, stone, brick chips, etc.), water, admixtures, etc in specific proportions. The strength and quality are dependent on the mixing proportions.

13 things to know to ensure quality of concrete

1. Selection of right building materials

- Cement

Cement was invented by Joseph Aspdin, which is a binder material used for construction that sets, hardens, and adheres to other materials to bind them together. It is seldom used on its own, but rather to bind sand and gravel (aggregates) together. Most common type of cement is OPC (Ordinary Portland Cement), which is available in 3 grades namely grade 33, grade 43 and grade 53. Make sure you choose the right cement for your project.

- Fine Aggregates (sand)

Fine aggregates are the particles that pass through 4.75 mm sieve and retain on 0.075 mm sieve.

- Coarse Aggregate

Coarse aggregates are the particles that retain on 4.75 mm sieve.

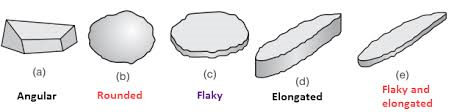

They come in various shapes: Rounded, Angular, Flaky, Elongated and Irregular are some. Angular aggregates assure high compressive strength in concrete because of the interlocking between the angular aggregates due to their higher specific surface area. Therefore, when you unload course aggregates (metal) in your site, above 65% should be angular and remaining 35% should be of the mix of other shapes.

- Water

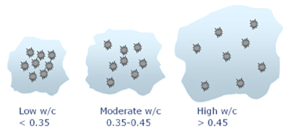

Amount of water used in the mix is the single most significant influence in concrete, on most or all of the properties. Any natural water that has no undesirable taste or color can be used for concrete.

Water to cement ratio (w/c) is the ratio of the amount of water to amount of cement used in concrete mix desgin. These two ingredients are responsible for binding everything together. For 1 bag of cement, 20 – 35 litres of water can be used. Strength and durability of concrete, once it is cured properly, is largely determined by W/C ratio.

2. Personnel

The basic requirement for the success of any quality control plan is the availability of experienced, knowledgeable and trained personnel at all levels. The designer and the specification-writer should have the knowledge of construction operations as well. Site engineer should have the clarity and knowledge of each and every work.

3. Equipment

Equipment used at the time of concrete are: Vibrator, Mixer machine, commonly used equipment used by mason.

4. Workmanship

The activities involved in the workmanship in all stages of concreting, i.e. batching of materials, mixing, transportation, placing, compaction, curing and finally testing and inspection should be top notch.

5. Concrete Mix Ratio

The nominal mixes of fixed cement-aggregate ratio (by volume) vary widely in strength and may result in under or over-rich mixes. Therefore, many specifications include minimum compressive strength of concrete to be used in construction projects. These mixes are termed standard mixes.

IS 456-2000 has designated the concrete mixes into a number of grades as M10, M15, M20, M25, M30, M35 and M40. In this designation the letter M refers to the mix and the number to the specified 28 day cube strength of mix in N/mm2.

The mixes of grades M10, M15, M20 and M25 correspond approximately to the mix proportions (1:3:6), (1:2:4), (1:1.5:3) and (1:1:2) respectively. Commonly used grades are M15 and M20 for residential buildings. Commercial buildings typically requires M25 or above grades.

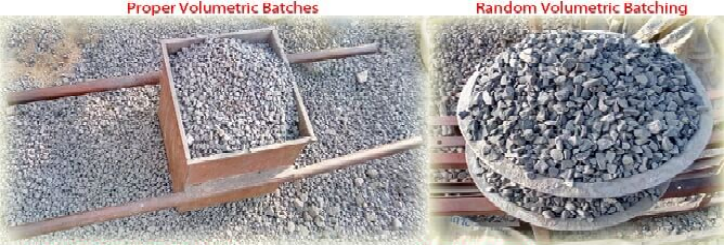

M15 is achieved using 1:2:4 mix ratio which means: 1 cubic meter cement, 2 cubic meter sand and 4 cubic meter metal. It is based on volume and not weight. Therefore, you can use a concrete pan or cubic box for measuring.

6. Batching of concrete

Batching refers to taking correct measurement of various materials used in concrete mix. Errors in batching are partly responsible for the variation in the quality of concrete.

7. Mixing of concrete

Mixing is one of the important factor in concrete and has two types:

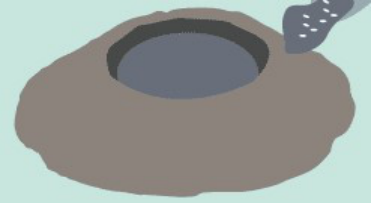

Manual or hand mixing: It is adopted for small works and this requires more cement than machine mixing for obtaining same strength of concrete. First consider a flat platform, which should not have contact with soil, for the mixing. W need to spread required sand first in the platform and then unload cement over it uniformly. Mix it well till the color becomes uniform. After mixing, add metal uniformly over this mix and again mix it well and arrange it in the shape given below.

Mechanical or machine mixing: Machine used for mixing concrete is termed as concrete mixer. First unload metal, then sand, then cement and mix it. After this, we need to unload required amount of metal and sand and take the mix.

8. Transportation

After mixing, concrete shall be transported and placed at site as quickly as possible without segregation, drying, etc. As soon as concrete is removed from the mixer, internal as well as external forces starts acting to separate the dissimilar constituents. So quick transportation to site is mandatory.

9. Formwork

Formwork is a structure, usually temporary, used to contain poured concrete and to mould it to the required dimensions. It is needed to support concrete till it is able to support itself. Below are some factors we need to consider:

- Try to use steel materials for this e.g.: shuttering sheet, jacky, span etc. If wood is used, you need to make sure they don’t have bends

- You should check the water levels and there shouldn’t be any gaps

- Edges should be fixed correctly

- You need to make sure there is adequate support provided

10. Placing

You should check the formwork and position of reinforcement before placing concrete to make sure that they are clean and free from dirty materials.

- After concrete mix preparation, it should placed within 30 minutes

- If the depth is 1.5m or above, you should use chute (shown in figure) place the concrete. Alternatively, one person can enter into the pit and take the concrete mix and place it.

- When the mix is moved to pan, slurry and metal should be uniformly mixed

- After placing has done, don’t apply water on that

- It should be laid continuously in order to prevent the formation of irregular lines

- If the surface is old, then it should be rough, cleaned and cement grouted

- Alignment of reinforcement and formwork should not be disturbed when concrete is place in RCC member

- During rainy time, concrete placing should not done

11. Compacting

When concrete is placed, structure of it will be loose. Therefore, you should compact properly to remove air bubbles and voids and ensure quality of concrete in your construction project. Commonly used compacting method is Vibrating method.

- Keep the vibrator in vertical directions inside the concrete

- You should handle it carefully in order to compact concrete layer uniformly

- Formwork should be tight in order to prevent leakage of mortar

- Vibration should be controlled by immersing internal vibrators for 5 to 15 sec at points 45 to 75cm apart

- Degree of compaction in all portions of concrete can only be regulated by making sure vibrator is placed vertical

- Lift should not be less than 15cm in order to avoid air trap

- Don’t touch form face with poker as it damages the form work and concrete

- Immerse vibrator through the full depth of concrete

- You should make sure to avoid under or over vibrating

12. Curing

Curing is the process of keeping the concrete moist and warm enough so that the hydration of cement can continue. First 7-10 days are the most critical, as any drying out during this young age can cause irreparable loss in the quality of concrete.

Generally, the long-term compressive strength of concrete moist in construction projects cured for 3-7 days will be about 60 per cent and 80% for the one moist cured for 28 days or more. Different methods of curing are:

- Water curing: Commonly used. Things to consider during curing:

- For main slab, you should retain water by giving bunds

- You can use spraying method in walls simultaneously

- Place gunny bags over beams, pillars etc

- Membrane curing

- Application of heat

- Miscellaneous

13. Inspection and Testing

Inspection and testing play a vital role in the overall quality control process for concrete in construction projects. You should do following tests:

- Crack and Honeycomb checking

- Ensure proper curing, use a curing log if possible (there are software available that can track curing logs)

- Do pre-casted cube testing on 14th and 28th days. Use rebound hammer test in case there are variations

- Check all coverings

- Check for any leakages

So here it is, a quick guide on concrete in construction and necessary quality checks. Share your thoughts below.

What to do if we find honeycomb after concreting?

If we found honeycombs then,1st step is to remove the dust using wire bush and painting brush. Apply any bonding agent on that. After 30min to 1 hr (time may vary based on the brand using), fill the honeycombs with GP2 grout, cement grout, or miracle bond repair epoxy. If the honeycomb is big, then pressure grout method we have to choose.