Prefabricated buildings construction is a lean approach for fast, quality delivery with reduced wastage. Prefabrication considerably reduces the time required for constructing buildings since the setup is quite easy. Let’s consider the scenario of residential projects (approx. 2000sqft). When we substitute the walls with cement fiberboards, the reduction in time is in the range of 18-20%. Not just that, prefabricated buildings are safer; whether it is the safety of workers or the building after construction.

Using Cement Board as Alternatives

Construction using cement fiberboard is way simpler than using bricks and mortar. Being a versatile material, you can use cement fiberboard in 10 different ways. Hence, you can use it as an alternative to many structural components of a building like walls, mezzanine floors, furniture, roofs, shelves, windows, doors, window and door frames, exterior wall cladding, etc. This board is a combination of cement and reinforcing fibers. It also contains a considerable amount of mica and cellulose. Let’s focus mainly on using cement fiberboard as an alternative to the traditional wall in the following sections.

Setting up cement fiber board

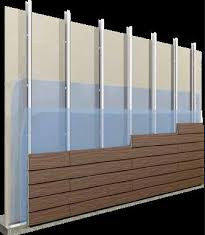

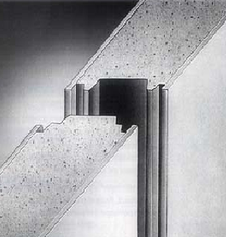

Setting up fiberboards as walls are more like an assembling job. Cement fiber boards are brought to the site and hung on the metal grid frame setup done prior to this. In-wall construction, the board is attached to the metal grid frame with self-fastening screws.

Various advanced products of cement fiber boards are available in the market. One of the popular ones is the Aerocon panels. Aerocon panels are a modification of cement fiberboard in which two fiber-reinforced cement sheets with a core separating sheets. The two panels are joined by a tongue and groove joining system. The core of the panels shall have binders like Portland cement and reinforcing bars such as cellulose and synthetic binders. The core shall contain materials such as pulverized fly ash, lightweight aggregates as fillers, and foaming agents.

Why is cement fiberboard better?

Cement fiber boards are more expensive than brick masonry materials. Though the added benefit in the reduction of skillful work and time balances this extra expense in material with that of traditional construction. Cement fiber boards are harder and hence pre-drilling is required. But, these boards reduce the need for plastering, wall chipping for electrical conducting works, spot plastering, etc.

The cement fiberboard is not susceptible to termite attack compared to the brick wall. These boards are lightweight and fire-resistant. The sound resistant and water repellent performance of this material is also noteworthy.

It’s a fact that shifting from the conventional construction practice using brick masonry to newer products like these is time-consuming. Also, it was noticed that customers are hesitant regarding the strength of cement fiberboard to be used as an outer wall material. Hence as an initiator, let’s start considering these materials for internal walls.

Prefabrication in the construction industry enhances the quality of the building. Because the factory-made products perform better than on-site construction. It’s important that we try these innovations in construction and reduce the intense labor requirement. This way, we can make various processes in the construction industry much effective.

In short, benefits of using fabricated buildings include,

improved safety,

consistent quality,

eco-friendly,

organized workplace,

cost savings,

shorter construction time,

less waste, etc.

So, when you plan a construction next, would you consider prefabricated buildings?

Prefab structures made using Cement Fiber board (CFB) are becoming increasingly trendy nowadays, due to the numerous advantages they offer. CFB is a composite material comprised of cement, cellulose fibers, and other materials – making it fire, water and termite resistant. Utilizing CFB for prefab building production presents a range of strengths like enhanced resistance, budget-friendly costs, environmental friendliness, fire protection, design versatility and minimal upkeep. All these benefits make it the perfect material for any type of constructions ranging from small dwellings to large commercial edifices.