Bison panel, a Cement Bonded Particle Board made in technical collaboration between NCL industries and Bison Werke of Germany combines the strength of cement and workability of wood. Its unique combination of properties gives it all-round superiority over most other boards. Its versatility in both internal and external applications is renowned. This board is the major breakthrough in developing a multi-purpose building board that can overcome almost all the drawbacks that are normally found in many-particle boards.

![]() Durability Review

Durability Review

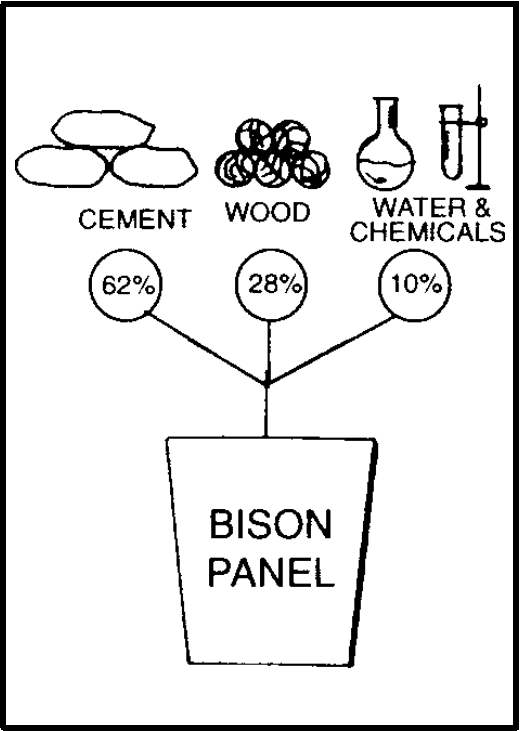

Bison panel is manufactured using wooden chips, cement water, and chemicals as shown in the diagram below. Hence it is a product of rare breed. Physical properties of the bison panel include great elasticity, screw holding capacity, and waterproofing capacity which makes it a fine option for construction.

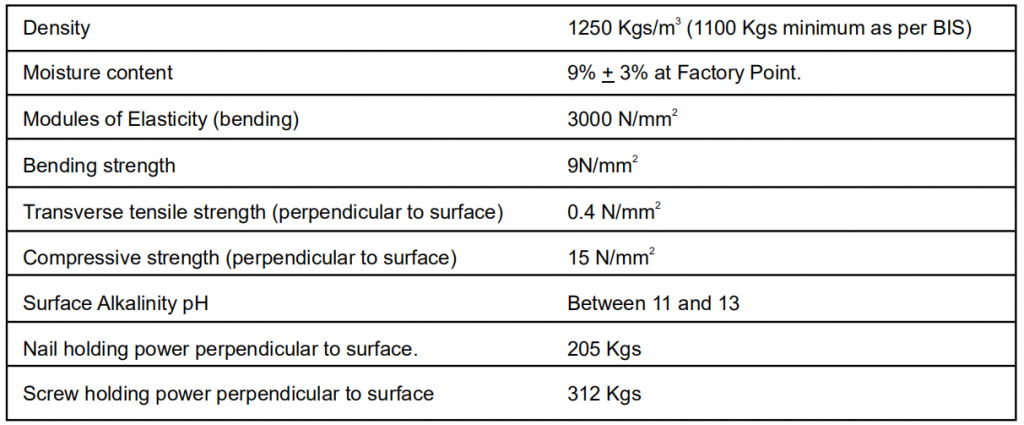

Physical properties of bison panel listed as :

Excellent fire and moisture resistance

Having seen the results of the product first hand, it is fair to say that bison panels showcase protection in fire and moisture hazards. In their case, customers are fortunate enough to have met with a solution to both these threats. Normally, fire-resistant products become putty at the hands of water and vice versa. But here, through these unique purpose particle bonds, we get a fairly resilient structure.

Superior quality of weather and termite resistance

With cement being the major constituent in the matrix of the board, it gives a satisfactory performance in the case of weather resistance. Since the wood particles in the board are mineralized and coated with cement, they do not get affected by termites either. This is not just a perfunctory claim, as we have seen the product withstand incorrigible weather conditions in vastly different geographical areas.

Weight contributes to strength

As the Bison Panel has high density, it weighs more. Higher density (1,250 to 1,350 kg cu.m.) contributes to the high compressive strength of the panel (15 N/MM2). For example, a 50 mm thick panel made with two 10 mm Bison Panels cladded on either side of a thin light gauge steel framework is able to take a vertical load of 1,100 kgs plus/per foot run of its length. The inconvenience due to higher weight might as well be ignored when compared with the strength given by the bison panel.

Warranty: Bison panel offers a warranty of up to 50 years for the product against manufacturing defects.

Feature Review

Available in varying thickness, ranging from 6mm to 40mm, bison panel stands to certain advantages among competitors whose range of products is significantly lower. Hence the favourability and the probability of usage is much higher in their case. The cement finishing and the cement color contributes to a more aesthetic look as well, as we have experienced the final result of this product first hand.

Dimensional stability

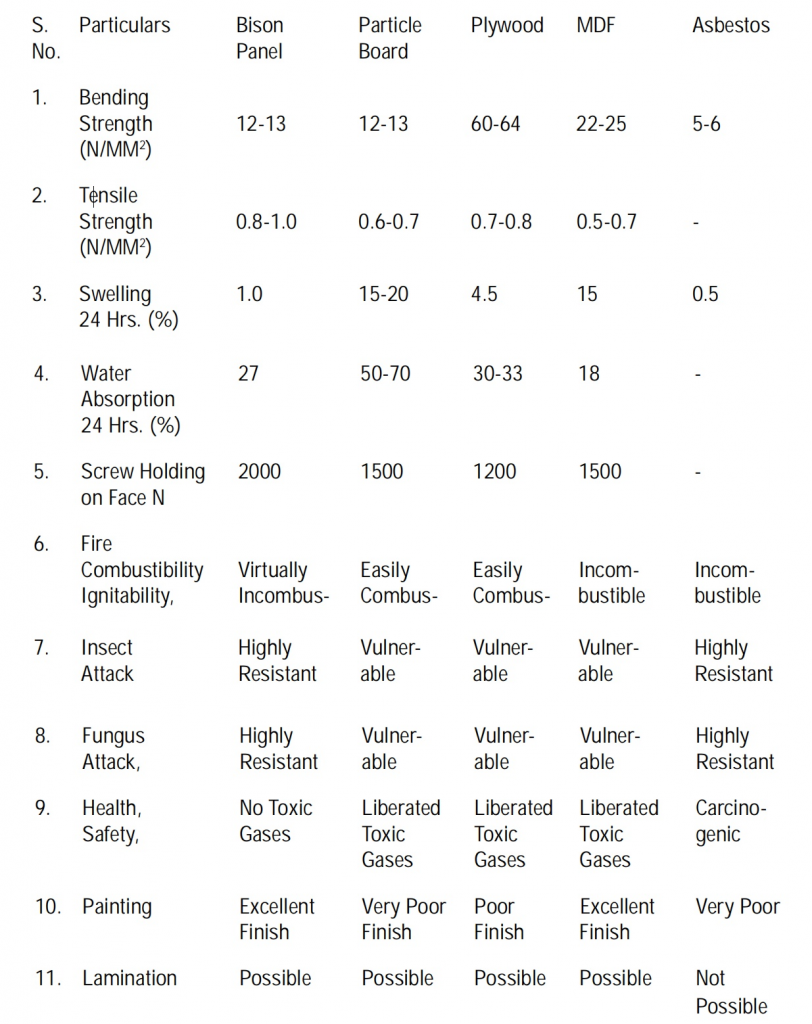

Due to uneven absorption of moisture products always fall prey to dimensional instability, but in the case of bison panels, though they absorb and release moisture like all wood particle boards, they do not suffer dimensional instability or variations because the swelling in the thickness of Bison Panel upon immersion in water for 24 hours is only 1.5 times which is negligible. The other boards swell 10 to 15 times more in comparison.

Ready for decoration

Bison Panel has a smooth surface and needs no surface preparation. The board can take any surface finish – from lime wash to water-bound distemper and from emulsion paint to lamination and paper overlays, whereas water-based paints cannot be applied on most of the other timber based boards. Such ready to use boards cut down the preparation time significantly and thus acts in accordance with the wishes of the respected consumer.

Safety of the material

In comparison to other boards, bison panel provides an advantage of added safety, in case of a fire hazard. The smoke emitted by this board in case of a fire is non-toxic, harmless and 100% asbestos-free

Sound Insulation

They provide great acoustic features and works as a sound absorbent.

Classy look

They have cement finished surfaces which provide a unique aesthetic look when compared to other boards .

Wide array of applications

Bison panels can be used for various applications like door panel inserts, false ceiling, mezzanine flooring, wall cladding, kitchen platform underlay, fixed furniture, paneling, partitions, and wall cladding for prefabricated houses, portacabins, temporary housing for workers, offices, and site offices.

Showing comparison of properties of different boards:

Sustainability Review

Sustainable to all weather conditions, they are very easy to handle and can last for longer periods of time.

Eco-friendly

The wood used is of plantation wood and species like Eucalyptus, Poplar, etc. Thus conserving regular forest wood and being more eco-friendly. It is the only truly sustainable building material. For every cubic meter of wood used in construction, one tonne of carbon dioxide is saved approximately.

Safe material

In case of a major fire accident, the immediate threat is always the smoke than the actual fire. But in the case of bison panels, even at the face of such an incident, one does not have to worry about the hazardous effect of the smoke; as they are non-toxic and harmless. Also, they are 100% asbestos-free. Hence, it can be stated that this particle bond which is a combination of eucalyptus and casuarina wood is the best bet for a safe and intact environment.

Good resistance

The dense and rigid structure of the panel provides a higher threshold of resistance against extreme climatic conditions; hence resulting in long-lasting structures. The board can withstand any temperatures from – 40 to + 90 deg.C.

Value Review

The unique combination of the product ( surmising wood chips and cement) makes it a fine option in the arena of construction. However, all the cement fiberboards ( made from cement and wooden pulp ) from companies such as Everest, Viska, Shera, etc are considered to be opponents of bison panel. The only comparison of the bison panel is with the heavy-duty (HD)cement fiber boards of the brands aforementioned. Even in that scenario, bison panel rates are 15-20% lesser than that of HD boards.

For the 16 mm thick 8*4 sheet MRP is at INR 2000/-. At the same time, a similar product from Shera board comes up to an MRP of INR 2761/-. In the case of an 8mm sheet used for ceiling and partition sheets, 6*4 bison panel costs about INR 756/-. At the same time, Everest’s heavy-duty board costs INR 864/-. You may explore the bison product range here.

Final Thoughts

Bison panel, a German technology cement-bonded particle, offers unique features like multifarious applications. It is sustainable to all weather conditions, environmental or eco-friendly, easy to handle, and cost-effective. If the buyers are thinking about a cement-based board solution at a moderate rate and superior quality, bison panel can act as a feasible option. In accordance with our experience, the services and the final products were always up to the mark. The service and support from the manufacturer can be termed as supreme in class. The higher period of warranty time ensures the quality of the product at an affordable price.

Disclaimer: BuildNext trades in all building materials irrespective of brand. Reviews on the Connect platform by BuildNext staff are kept impartial, with maximum information taken from the brand itself or feedback from customers.